Plymouth, MA, July 26, 2017. Flexo Concepts® is excited to announce that Packaging Plast will begin shipping all its carbon fiber chambers with the TruPoint Green doctor blade beginning in September of this year.

Plymouth, MA, July 26, 2017. Flexo Concepts® is excited to announce that Packaging Plast will begin shipping all its carbon fiber chambers with the TruPoint Green doctor blade beginning in September of this year.

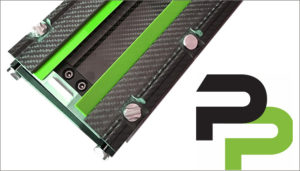

The Italian OEM manufactures its chambers from a carbon fiber material that offers stiffness and durability in ultra-lightweight construction. Other benefits include reduced water and solvent consumption, easy blade changes and extended blade and end seal life.

TruPoint Green is a next-generation polymer doctor blade for corrugated printers producing mid-level graphics. The blade’s mechanical properties and composition allow it to meter more effectively than UHMW with significantly longer blade life than steel. TruPoint Green in combination with the carbon fiber chamber design delivers better print quality and provides printers with considerable savings on the inking systems of their presses.

Totally in-house designed, assembled and manufactured with 100% structural carbon fiber, Packaging Plast’s doctor blade chambers can be installed on CI as well as in-line flexo presses. The chambers are suitable for the full spectrum of flexo printed products, from corrugated board to flexible film, including tissue paper. For more information, visit www.packagingplast.com.

To learn more about TruPoint Green, go to www.flexoconcepts.com or call 508-830-9506. A complete press kit can be downloaded at www.flexoconcepts.com/media.

About Flexo Concepts

Headquartered in Plymouth, Massachusetts, Flexo Concepts manufactures TruPoint® doctor blades and wash-up blades, and MicroClean™ dry media anilox cleaning systems. All products are designed to improve print quality and reduce operational costs for flexographic and offset printers. Flexo Concepts maintains distribution locations in North America, South America, Europe, Asia, Africa and Australia. For more information about the company and its products visit www.flexoconcepts.com. For regular updates, follow Flexo Concepts on Facebook and Twitter.