Ever seen your perfect print job turn into a messy, chaotic artwork? If you’re a label printer, you’ve probably faced the nightmare of UV ink spitting. But don’t worry, we’ve got the solutions you need to reclaim your sanity!

1. Start with Some TLC

Ensure your equipment is in top shape. Clean the anilox roll, inspect the doctor blade holder or chamber, and lower the doctor blade pressure for a perfect wipe. Minor tweaks can work wonders.

2. Opt for New Anilox Roll Engravings

Traditional engravings can hinder UV ink flow. Because UV inks have a viscosity of 5-7 times greater than that of water-based or solvent-based formulations, different anilox configurations may be required. New elongated hexagonal cell engravings, or even newer channeled engravings, can improve ink transfer and reduce or eliminate ink spitting.

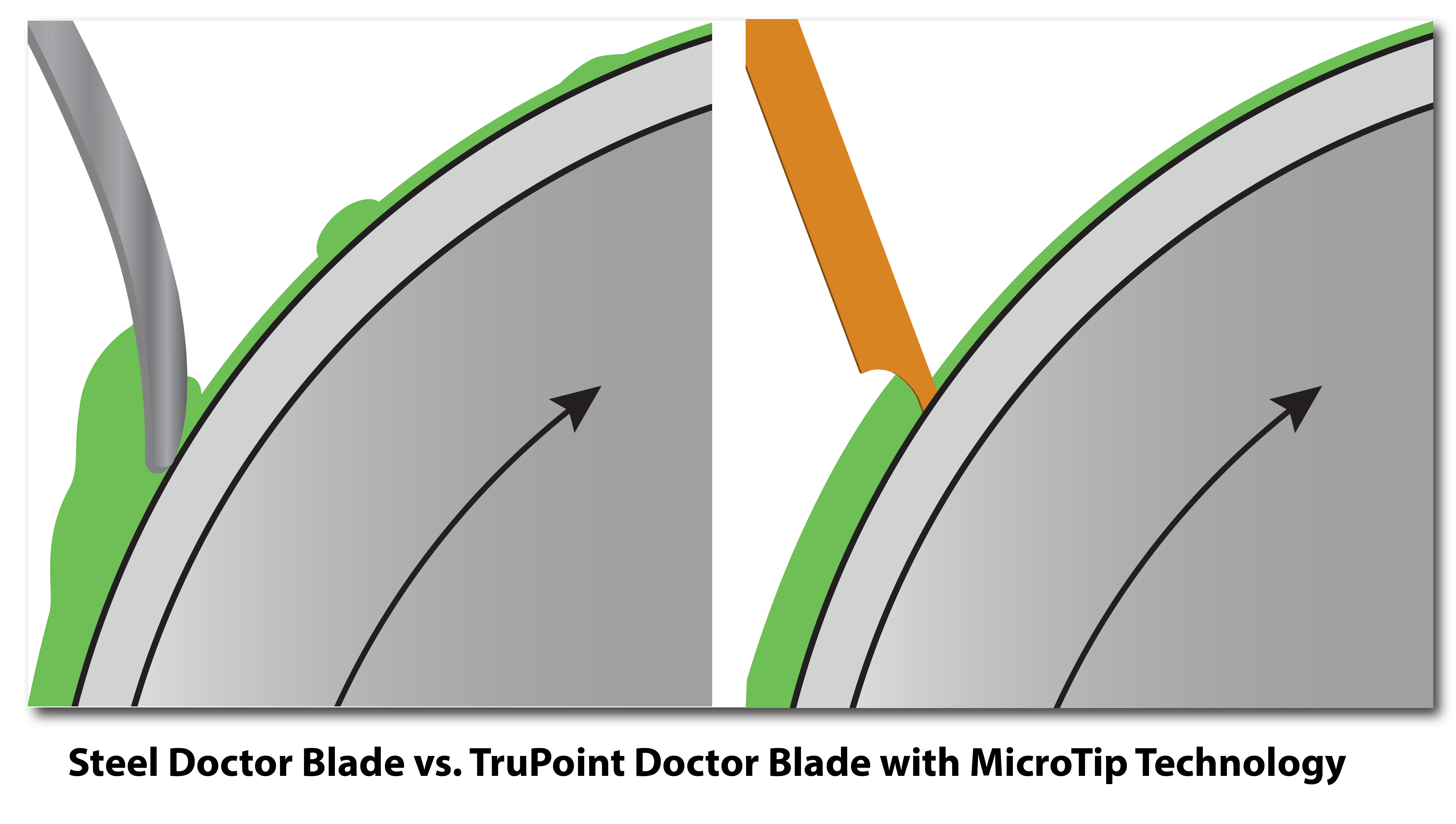

3. Try a Different Doctor Blade

Doctor blades are an easy variable to change when up against UV ink spitting. It’s a low-cost part with a big impact. TruPoint polymer doctor blades are a fantastic choice for handling UV inks. Why? Our unique MicroTip edge ensures consistent ink metering but more importantly, TruPoint polymer materials have a lower surface energy than steel.

This lower surface energy reduces the attraction of the UV ink to the doctor blade and allows for a cleaner ink transfer. Steel’s high surface energy attracts UV ink, causing it to accumulate on the backside of the blade and then release. This is UV ink spitting!

Taming UV ink spitting can be easier than you think. Regular maintenance and the right doctor blade can make all the difference. Don’t let ink-spitting drive you crazy; we’re here to help!