If you are a producer of simple corrugated graphics, you are probably very familiar with UHMW as the best solution to optimize doctor blade life and pressroom safety. However, if your customers expect higher print quality for brand consistency and marketing appeal, steel might be your blade material of choice.

If you are a producer of simple corrugated graphics, you are probably very familiar with UHMW as the best solution to optimize doctor blade life and pressroom safety. However, if your customers expect higher print quality for brand consistency and marketing appeal, steel might be your blade material of choice.

Many printers producing high graphics don’t want to accept the downside of steel – short blade life, potential for anilox scoring and risk of serious injury to press operators. To address this market need, Flexo Concepts has introduced the TruPoint Green® doctor blade for high graphics corrugated printers who prefer a plastic blade. Green can handle these metering requirements while delivering the added benefits that polymer materials are known for – long blade life and safety.

Corrugated Box Market Evolution

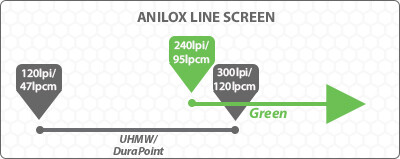

UHMW has always been the “standard” doctor blade used in corrugated applications. However, the function of the corrugated box has evolved from a simple “this side up” logistics package to eye-catching promotional packaging that also serves as a display vehicle. Today’s graphics requirements are exceptionally challenging, and more colors, finer plate screens, half-tones and higher  anilox line counts are being used to produce attractive point of sale containers. Predictable ink density and color control are essential to ensure manufacturers’ brand consistency. In these demanding graphics applications, however, UHMW doesn’t perform well. Until recently, a steel blade was often necessary to achieve a precise wipe of the higher line screen anilox rolls required to produce this level of work.

anilox line counts are being used to produce attractive point of sale containers. Predictable ink density and color control are essential to ensure manufacturers’ brand consistency. In these demanding graphics applications, however, UHMW doesn’t perform well. Until recently, a steel blade was often necessary to achieve a precise wipe of the higher line screen anilox rolls required to produce this level of work.

Faced with this market evolution, some printers continue using their current blades and accept limitations on print quality or blade life. For example, as line screens increase, standard UHMW will produce dirty print due to its large contact area with the anilox roll. On the other hand, steel blades wear more quickly, damage the anilox roll, and can easily injure press operators.

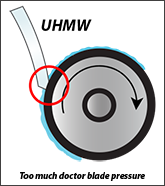

Modified traditional blade products can offer a solution in this space up to a point. By placing a lamella, or stepped edge on standard UHMW, the blade can achieve a slightly smaller contact area with the roll and metering quality can be improved on line screens up to around 360 lpi or 142 l/cm. (Keep in mind that print quality will diminish as the blade wears and contact area grows.) Unfortunately, a lamella tip does not solve the problem of doctor blade mechanical creep (or bending). UHMW is notorious for its poor mechanical creep properties, meaning the material tends to bend and lose its shape under a consistently applied force. Over time, the blade angle decreases and the contact area increases. UHMW’s poor creep quality often results in reduced graphics quality, requires increased blade-to-anilox pressure to achieve a clean wipe and causes more press downtime for blade adjustments and changes.

Modified traditional blade products can offer a solution in this space up to a point. By placing a lamella, or stepped edge on standard UHMW, the blade can achieve a slightly smaller contact area with the roll and metering quality can be improved on line screens up to around 360 lpi or 142 l/cm. (Keep in mind that print quality will diminish as the blade wears and contact area grows.) Unfortunately, a lamella tip does not solve the problem of doctor blade mechanical creep (or bending). UHMW is notorious for its poor mechanical creep properties, meaning the material tends to bend and lose its shape under a consistently applied force. Over time, the blade angle decreases and the contact area increases. UHMW’s poor creep quality often results in reduced graphics quality, requires increased blade-to-anilox pressure to achieve a clean wipe and causes more press downtime for blade adjustments and changes.

In moderate graphics applications, graphite, polyacetal and Teflon-filled Delrin can be used to replace steel. These materials will deliver decent metering and longer blade life on line screens ranging up to 550-600 lpi or 217-236 l/cm. The blades are thinner and bevels ranging from 22°-45° can be applied to further improve contact area (which, again, grows as the blades wear). The  problem with these blades, however, is their thickness in comparison to the blade holder. On press models where the chamber is designed to hold a .060”-.080” UHMW blade, these .020”-.040” thick blades require a shim or modification which can slow down changeovers.

problem with these blades, however, is their thickness in comparison to the blade holder. On press models where the chamber is designed to hold a .060”-.080” UHMW blade, these .020”-.040” thick blades require a shim or modification which can slow down changeovers.

A Blade Designed to Replace Steel in Moderate to High Graphics Applications

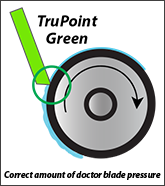

The need emerged for a doctor blade that was stiff like steel, resistant to bending, long-lasting, safe and compatible with current blade holders, sparking the development of the TruPoint Green doctor blade. TruPoint Green was created in Flexo Concept’s Doctor Blade Innovation Lab and tested and refined for over two years before entering the market in 2017.

TruPoint Green is a custom compounded next generation polymer material that is stiff, durable, and more than 4x more resistant to bending than UHMW. The construction allows for a fine contact area with the anilox roll and better print quality throughout the entire life of the blade. The rigid material and creep resistance allow the blade to maintain a fine area of contact with the anilox roll throughout the life of the blade. Green is capable of metering mid-to-high anilox line screens effectively, delivering better control over color as anilox line screens increase. The material is also safe to handle and has a much lower wear rate than steel.

TruPoint Green is a custom compounded next generation polymer material that is stiff, durable, and more than 4x more resistant to bending than UHMW. The construction allows for a fine contact area with the anilox roll and better print quality throughout the entire life of the blade. The rigid material and creep resistance allow the blade to maintain a fine area of contact with the anilox roll throughout the life of the blade. Green is capable of metering mid-to-high anilox line screens effectively, delivering better control over color as anilox line screens increase. The material is also safe to handle and has a much lower wear rate than steel.

For box makers struggling to achieve the high-quality graphics demanded from today’s consumers, there is finally an ideal blade solution. The next generation TruPoint Green doctor blade is designed to deliver the best of both steel and plastic in corrugated pressrooms by producing high level graphics effectively, efficiently economically and safely.