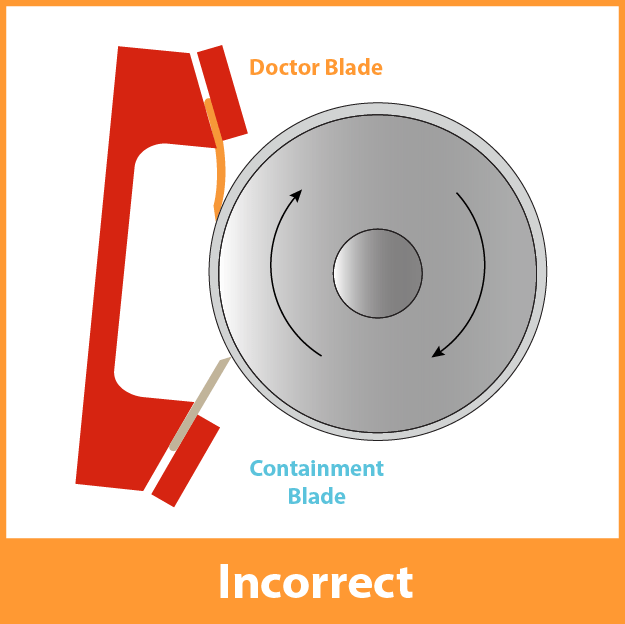

The Right End Seals Will Prevent Leaks in Your Doctor Blade Chamber System

Christine Duggan2022-03-08T15:53:43-05:00In an enclosed doctor blade chamber system, the job of the end seals is to keep the coating or ink from leaking out of the ends of the [...]